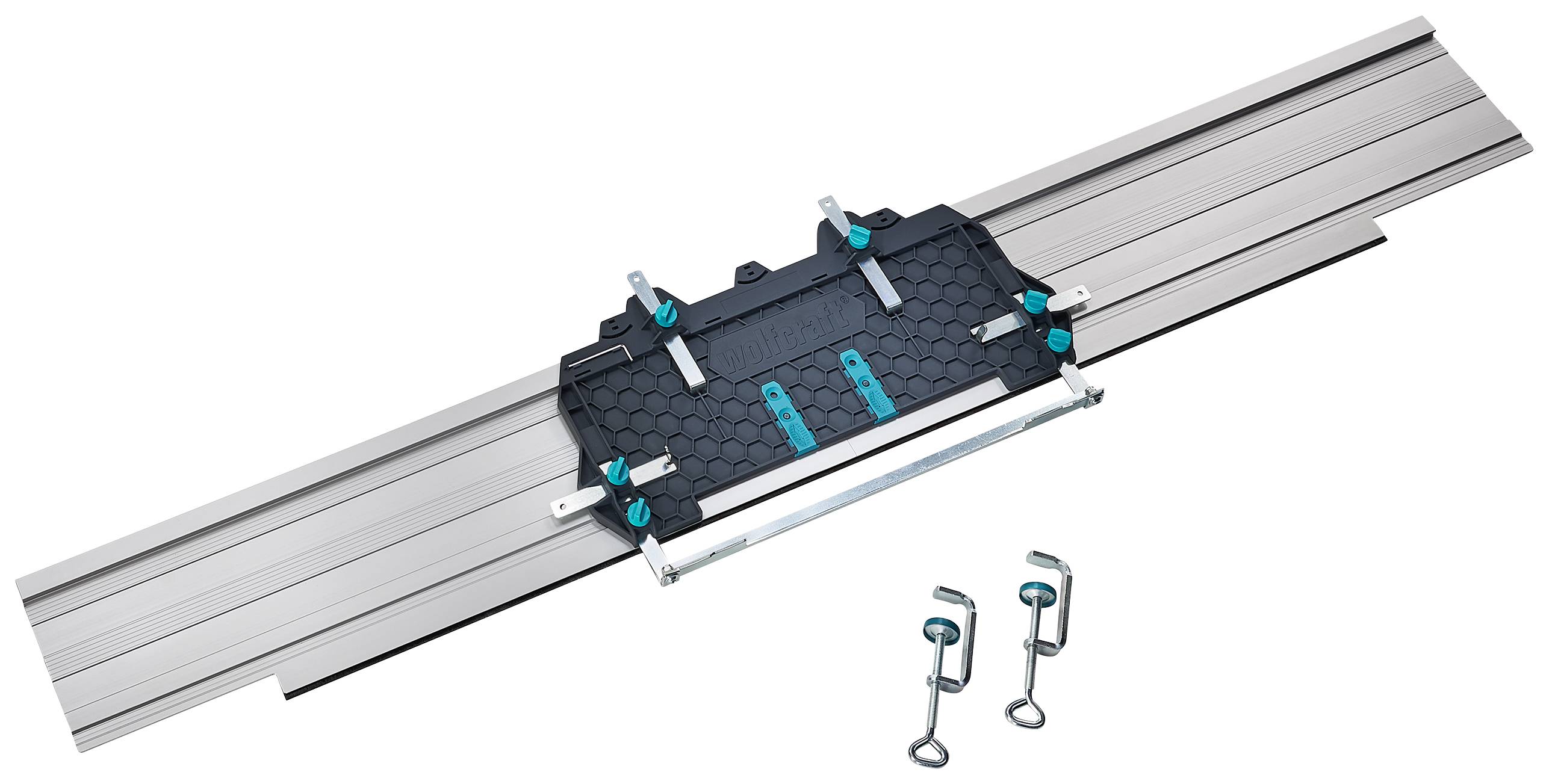

After a simple setup you will achieve high accuracy with excellent controllability. This allows you to make longitudinal and cross cuts (up to 610 mm) in plywood, MDF and other big boards.

Start your projects with straight, accurate cuts without tears with your circular saw and the Rip-Cut.

LOWES ACCU RIP PLUS

I have something called an accu-rip and starting the cut is not the problem,its finishing the cut,The guide is too short so youre free hand for about six inches.Ive theought about addiding some 1X,but then the setup would be messed up.What Kregg has done is a very simple solution that I cant figure out why the other manufactures havent done.The gizmo I have works,but you cant convert to left handed which would be a plus for me.These guides do work especially for repetative cuts for fast jobs,or if your like me I have to break down the table saw and set it up when I need to use it(live in a condo) so if I dont need the table saw it the guide makes quick work out of the project.Personally I would like to see the front extend a few more inches.but as I said before the start of the cut is not the problem especially with the the guide that I have,its too short for the finishing cut.Kreg Rip-Cut and Kreg Accu-Cut Combo Promotion Pack

It’s a super easy, precise, and affordable way to break down large panels for almost any project. It features a durable design including a solid aluminum guide rail, ultra-durable impact resistant plastic, an easy-to-read precision adjustable scale, and a reversible guide arm which works whether you’re left or right handed. The Rip-Cut™ is a no-nonsense, straight forward, precision accessory for your circular saw that is so incredibly affordable it will pay for itself in no-time. No measuring, no marking, no chalk lines – the Rip-Cut™ quickly and easily attaches to almost any circular saw, letting you cut pieces up to 24” wide with tremendous accuracy. The Rip-Cut™ is an incredibly handy tool which speeds and simplifies the process of ripping down large plywood and MDF panels. No more taking your work to the saw, instead take the saw to your work.

There is an easier way! There is a better way. Ripping down large panels into smaller more manageable workpieces can be one of the trickiest, most intimidating, and expensive steps of any wood project. Even for experienced woodworkers ripping with the nicest table saws, you’re still forced to lift large heavy panels, balance them carefully to avoid binding and bowing, while at the same time trying to support the finished workpieces and waste material as they exit the saw.

0 kommentar(er)

0 kommentar(er)